Type 1: Difference between revisions

WestyMan1971 (talk | contribs) No edit summary |

WestyMan1971 (talk | contribs) |

||

| (156 intermediate revisions by the same user not shown) | |||

| Line 4: | Line 4: | ||

| caption = 1949 Beetle Type 11 (Export Model) | | caption = 1949 Beetle Type 11 (Export Model) | ||

| manufacturer = [[Volkswagen]] | | manufacturer = [[Volkswagen]] | ||

| aka = {{ | | aka = {{plainlist| | ||

* Beetle | |||

* Bug | |||

* [[Super Beetle]] | |||

* [[1200]]/[[1300]]/[[1302]]/[[1303]]/[[1500]] | |||

* Käfer | |||

* Carocha | |||

* Coccinelle | |||

* Fusca | |||

* Vocho}} | |||

| designer = [[Ferdinand Porsche]] | | designer = [[Ferdinand Porsche]] | ||

| production = 1938–2003: 21,529,464 built | | production = 1938–2003: 21,529,464 built | ||

| | | variants = {{plainlist| | ||

* [[ | * [[1200]] | ||

* [[ | * [[1300]] | ||

* [[ | * [[1302]]/[[1303]]}} | ||

* [[ | | derivatives = {{plainlist| | ||

* [[ | * [[Karmann Ghia]] (Type 14) | ||

* [[Type 181|VW Thing / Trekker]] (Type 181/182) | |||

* [[ | * [[Kübelwagen]] (Type 82) | ||

* [[ | * [[Kommandeurswagen]] (Type 87) | ||

* [[Schwimmwagen]] (Types 128 and 166) | |||

* [[Meyers Manx]] | * [[Transporter]] (Type 2) | ||

* [[ | * [[Type 3|1500/1600]] (Type 3) | ||

* [[Type 4|411/412]] (Type 4) | |||

* [[Brasília|Brasília / Igala]] (Type 321) | |||

* [[Meyers Manx]] | |||

* [[Fiberfab Avenger GT]] | |||

* [[Porsche 356]]}} | * [[Porsche 356]]}} | ||

| engine = {{plainlist| | |||

* 1100 cc [[Type 1 engine|Type 1 H4]] (1938-1953) | |||

* 1200 cc [[Type 1 engine|Type 1 H4]] (1954-1965) | |||

* 1300 cc [[Type 1 engine|Type 1 H4]] (1966) | |||

* 1500 cc [[Type 1 engine|Type 1 H4]] (1967-1970) | |||

* 1600 cc Single-port [[Type 1 engine|Type 1 H4]] (1970 option) | |||

* 1600 cc Dual-port [[Type 1 engine|Type 1 H4]] (1971-2003)}} | |||

| transmission = {{plainlist| | | transmission = {{plainlist| | ||

*4-speed [[manual transmission|manual]] transaxle | *4-speed [[manual transmission|manual]] transaxle | ||

| Line 35: | Line 45: | ||

*3-speed [[Semi-automatic transmission|semi-automatic]]; ''[[Autostick]]'' (1967–1976)}} | *3-speed [[Semi-automatic transmission|semi-automatic]]; ''[[Autostick]]'' (1967–1976)}} | ||

| wheelbase = {{convert|2400|mm|in|1|abbr=on}} | | wheelbase = {{convert|2400|mm|in|1|abbr=on}} | ||

}} | }} | ||

The '''Beetle'''—officially the '''Type 1''', is an economy car that was manufactured and marketed by Volkswagen (VW) from 1938 until 2003. | |||

It was designed by [[Ferdinand Porsche]] and features an air cooled rear-engine, two door coupe or cabriolet body-on-chassis design. | |||

= History = | |||

==== Josef Ganz's "Maikäfer" and the Standard Superior ==== | |||

[[File:Maikaefer CentralGarage-1.jpg|thumb|left|Josef Ganz's Maikäfer prototype as it is today.]] | |||

The idea of a "people's car" can traced as far back as 1923, when a young Jewish Hungarian engineering student named [[Josef Ganz]] began sketching concepts for a "car for the masses." Ganz's design featured a mid-mounted engine, independent suspension and a streamlined body. | |||

Being a student, Ganz did not have the funding to produce a prototype of his design, but instead began submitting articles on automotive design for various publications. Shortly after completing his studies in 1927, Ganz was hired as editor-in-chief of Klein-Motor-Sport (later renamed Motor-Kritik), where he continued to write articles promoting progressive design and the creation of a car for the average citizen. | |||

In 1929, Josef Ganz contacted motorcycle manufacturers [[Zündapp]], Ardie and DKW with assistance to build a prototype of his concept. The first prototype, the Ardie-Ganz, was built at Ardie in 1930 and a second one was completed at Adler in 1931, which was nicknamed the Maikäfer (‘May-Beetle'). | |||

Production of the first car based on Josef Ganz's designs and patents began in 1933. The Standard Superior, built by Standard Fahrzeugfabrik, featured a body-on-tubular chassis, 2-stroke air cooled mid-engine, and independent suspension with rear swing-axles. This car was advertised as the German "Volkswagen," or "people's car," pre-dating the incorporation of [[Volkswagenwerk GmbH]] in 1937. Superior production ceased in 1935. | |||

Due to the antisemitic policies of the Nazi Party, Ganz's influence on the development of the Beetle was largely forgotten and has often been left out of official Volkswagen history. His contribution is still widely debated to this day. | |||

==== Ferdinand Porsche's prototypes ==== | |||

[[File:Zundapp.jpg|thumb|left|Porsche Type 12]] | |||

In 1931, Zündapp requested Austrian engineer [[Ferdinand Porsche]] design and build a prototype for an "everyman's automobile." This led to the development of three prototypes (two saloons and one coupe) known as the [[Porsche Type 12]]. These prototypes features a U-channel center beam chassis, leaf spring suspension, worm-gear steering and hydraulic drum brakes. The drivetrain consisted of a Zündapp-built five-cylinder radial engine (as opposed to Porsche's preferred [[flat-four engine]]) and a combined gearbox differential transmission joined by a wet single disc clutch. The Type 12 laid the basic design foundation for what would eventually become the Beetle. | |||

In 1932, Porsche was contacted by [[NSU Motorenwerke]] to design and build a prototype automobile. NSU wished to return to manufacturing cars after a period of exclusively building motorcycles. While Zündapp has requested use of their radial engine, NSU placed no such restrictions and gave Porsche full control of development. This resulted in the construction of three prototypes, with two different body styles, called the [[Type 32]]. These prototypes featured the rear air-cooled flat-four engine, central tube frame, front axle, rear swing axle and torsion bar suspension that would become quite familiar to Volkswagen owners in the subsequent decades. | |||

==== Adolf Hitler ==== | |||

In 1924, a young Adolf Hitler spent nine months in Landsberg Prison as a result of his Nazi Party's failed coup the year prior. While serving his sentence, Hitler read several books about Henry Ford's development of mass production techniques. Hitler showed great interest in automobiles, despite never having learned to drive. The future chancellor came to admire Ford and made it among his political ambitions to bring affordable transportation to the people of Germany in the same manner which Ford had done in the United States. | |||

Upon Hitler's rise to power in 1933, the German auto industry was limited to luxury models, which few Germans could afford. Only one German out of 50 owned a car. The newly appointed chancellor began to form plans to utilize state resources to develop an affordable automobile. At the 1933 Berlin Auto Show, he viewed a presentation of the Standard Superior by Josef Ganz. Hitler was quite impressed with the revolutionary design and low price of the Superior. Ganz, however, was arrested by the Gestapo shortly thereafter on falsified charges of blackmailing the German automotive industry. Ganz was eventually released and quickly fled Germany. | |||

In May 1934, at a meeting at Berlin's Kaiserhof Hotel, Hitler outlined his request for a basic vehicle that could transport two adults and three children at 100 km/h while not using more than 7 litres of fuel per 100 km. The engine had to be powerful enough for sustained cruising on Germany's Autobahn, which was under construction at the time. Parts needed to be widely available and quickly and affordably exchanged. The engine had to be air-cooled to avoid radiators freezing during the winter months. It's platform must be easily adapted to a variety of uses, including military applications. This "People's Car" was to be made available to citizens of Germany through a stamp booklet savings plan, for under 1000 Reichsmarks. (At the time, the average weekly income was around 32 Reichsmarks.) | |||

By June 1934, Hitler had assigned the task of development to Ferdinand Porsche. A design team was quickly assembled which included future Porsche designers Erwin Komenda and Karl Rabe. By October 1935, two prototypes known as, a sedan (V1) and convertible (V2), were complete and ready for testing. By 1936, three more prototypes (V3) were finished. These cars were designated [[Type 60]] and built by hand in Porsche's [[Stuttgart]] workshop. | |||

Hitler was impressed with the V3 prototype at the Berlin Auto Show and immediately ordered that it enter production. The Reichsverband der Deutsche Automobilindustrie, a special interest group representing German automakers, immediately pushed back against further development, seeing the low cost of the car as a threat to their business. This in turn caused Hitler to declare the project a wholly state-run enterprise of the national labor union, Deutsche Arbeitsfront. | |||

A further thirty development models, known as V30, were produced for Porsche by Daimler-Benz. These vehicles underwent demanding tests through a variety of terrain and environmental conditions. Overall, these cars were subjected to a combined 1.8 million miles over the course of 1937. Though lacking a rear window, all V30s shared the distinctive round shape and the air-cooled, rear-mounted engine of final production models. | |||

The final design added a split rear windshield. In 1938, 44 pre-production models known as the [[VW38]] were built by hand in Stuttgart. The very first convertible model from this batch (chassis 38/31) was presented to Hitler as a gift. Fifty more cars followed in 1939 ([[VW39]]), and though still hand-built, some parts utilized the new stamping dies built for production. | |||

==== The KdF Wagen and a new factory ==== | |||

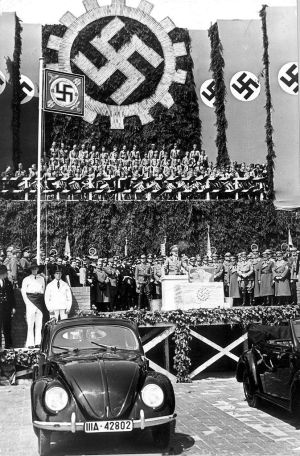

[[File:Cornerstone ceremony 1938.jpg|right|thumb|Laying the cornerstone on May 26, 1938]] | |||

By 1937, it was decided that a new factory was needed for production of the "people's car." Land was seized in Northern Germany, along the banks of the Mitteland Canal in the village of Fallersleben. Construction of the new factory began in February 1938. | |||

On May 26, 1938, a cornerstone-laying ceremony was held at the site of the new factory with typical Nazi-party fanfare and propaganda photo-ops. In the speech given by Adolph Hitler, he announced the new automobile to be built on the site will be named "Kraft-durch-Freude-Wagen" ("Strength Through Joy Car," abbreviated to KdF-Wagen) after the leisure organization operated by Deutsche Arbeitsfront. He also outlined his plan for construction of a grand factory city known as "Stadt des KdF-Wagens bei Fallersleben" ("City of the Strength Through Joy car at Fallersleben") to be built on the southern side of the canal. | |||

Production of the KdF Wagen was scheduled to begin in the Autumn of 1939. Nazi propaganda claimed the new factory was expected to produce 500,000 vehicles per year, all for the benefit of the German people. However, only about 200 vehicles were produced prior to the outbreak of war. Most of these early production vehicles were given to Nazi Party officials and few, if any, citizens received their car through the stamp-booklet savings plan. | |||

==== Wartime production ==== | |||

On September 1, 1939, Nazi Germany invaded Poland. Two days later, France and Britain declared war on Germany, signaling the start of World War II. | |||

Almost immediately, the factory at KdF-Stadt shifted to wartime production. The primary vehicles produced during this time were the Porsche-designed Type 82 [[Kübelwagen]] and Type 166 [[Schwimmwagen]]. A handful of light vehicles based on the KdF-Wagen were constructed, such as the Type 82E [[Kommandeurswagen]]. The manufacturing resources of the factory were also used to produce other military equipment including stoves, aircraft parts and assemblies for the V1 flying bomb. A very limited number of civilian KdF-Wagens were built during the war, which were primarily handed to high-ranking Nazi Party members. | |||

Production at KdF-Stadt was halted in 1944 after the factory sustained significant damage due to Allied bombing. Much of the critical equipment was moved into bunkers, with expectation that production would resume after hostilities ceased. | |||

Due to gasoline shortages in the late stages of the war, a small number of vehicles were converted to utilize wood-burning gas generators. These became known as "[[Holzbrenner]]" Beetles. | |||

In early 1945, the tide of war had turned. American troops were advancing deeper into Germany and over two thirds of the factory lay in ruin. Some workers, many of whom were foreign forced laborers, began destroying as much as they could of what was left. | |||

==== Allied occupation ==== | |||

KdF-Stadt was captured by US troops on April 11, 1945. Over 7,700 forced laborers were liberated from the factory. On May 25, 1945, the city was renamed Wolfsburg, after the nearby Wolfsburg Castle. The Americans occupied Wolfsburg until June 1945, at which time it became part of the British Occupation Zone. | |||

The British intended to dismantle the factory and ship all useable assets to Britain under the Morgenthau Plan. However, no British automaker was interested in the factory. Sir William Rootes, head of the British Rootes Group, told Hirst the project would fail within two years, is quoted as saying the car "is quite unattractive to the average motorcar buyer, is too ugly and too noisy. If you think you're going to build cars in this place, you're a bloody fool." | |||

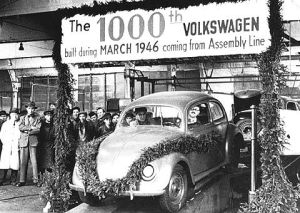

[[File:1000th Volkswagen.jpeg|thumb|right|The 1000th Volkswagen rolls off the line in 1946.]] | |||

Responsibility for the city and the factory then fell to a division of the Royal Electrical and Mechanical Engineers commanded by Major [[Ivan Hirst]]. At the time, the bombed-out factory was being utilized as a repair shop for Allied military and transport vehicles. Hirst soon discovered that much of the original tooling and parts remained undamaged. His team assembled a few complete vehicles from existing parts and saw the potential in the quirky little car. Realizing that occupation forces required a cheap and reliable form of transportation during Germany's reconstruction, Hirst saw an opportunity. The car was presented to the British Military, who promptly placed an order for 20,000 vehicles. Two weeks later, the order was doubled to 40,000. | |||

Hirst quickly grew the workforce from the remaining 450 post-war workers to over 6,500 employees. At this time, the car reverted to it's original name, "Volkswagen" (People's Car) and the model was designated the "Type 1." The first production Type 1 rolled off the assembly line on December 27, 1945. By March 1946, the Wolfsburg plant was producing 1,000 cars per month, painted army green for the British military. Early production numbers were limited by rationing and a shortage of raw materials, such as steel, batteries, textiles, and glass. Early Beetle roof sections were fashioned out of two pieces of steel, due to larger sheets being unavailable. Hirst convinced the British government to allocate the necessary materials, as the operation of the factory stimulated economic growth and increased employment during post-war reconstruction. | |||

1947 signaled a transition into building a civilian version of the Type 1. For the first time, chrome bumpers, hubcaps and body trim were fitted. Engine displacement was increased to 1131cc and had an output of 25hp. Models destined for export markets were designated and marketed as the Type 11. Civilian output reached 9,000 units in 1947, which increased to almost 20,000 in 1948. | |||

In March 1948, the British offered the company to Ford, free of charge. Henry Ford II and Ford chairman Ernest Breech travelled to West Germany to tour the factory. When Ford asked Breech for his opinion, Breech said, "Mr. Ford, I don't think what we're being offered here is worth a damn!" | |||

==== Returning Volkswagen to German control ==== | |||

After the British-led restart of production and failing to find a buyer for the company, Hirst began to look for a successor to return day-to-day operations back to the Germans. Former Opel director [[Heinrich Nordhoff]] was offered a position as manager. Despite being highly critical of the Volkswagen's unconventional engineering in the past, Nordhoff had few other opportunities. Though he was never a member of the Nazi Party, he had been barred from work in the American sector due to his position at the Opel factory building German military vehicles. Nordhoff accepted and took control of the Wolfsburg plant on January 1, 1948. | |||

Under Nordhoff's leadership, the British Military Government slowly took a backseat to operations. On October 8, 1949, ownership of Volkswagenwerk GmbH was transferred to the newly-formed West German government. | |||

==== Expansion and export ==== | |||

Upon joining Volkswagen, Heinrich Nordhoff brought years of managerial, technical, and mass production experience to the young company. Nordhoff settled on a "one model" plan, where the product would retain a similar outward appearance, with minor changes made to improve performance and efficiency. Right away, he saw the need to expand the market. Though under British control, a strong export market had been created in a handful of European countries, Nordhoff realized that in order to survive, Volkswagen would have to break into the American market. At the time, The United States had the strongest post-war economy and most stable currency in the world. | |||

Norhoff recruited [[Ben Pon]], a highly successful Dutch importer, to introduce the Volkswagen to the American market. Pon traveled to New York in 1949, bringing a Beetle along, to try and convince European Car dealers to sell the car. After a month of attempts, Pon was ultimately unsuccessful. He ended up selling the Beetle for just $800 in order to pay for his expenses. While a few VWs had been brought back to the United States by returning GIs, Norhoff was determined to break into the market. He traveled to the US himself later in 1949, but was no more successful, again selling only one car. | |||

In 1950, Max Hoffman took interest in Volkswagen. Hoffman was an established and successful American importer of European autos. Hoffman established a small American sales network which managed to sell 330 VWs in the first year. Many of the dealers who purchased Volkswagens did so in hope to establish a good report with Hoffman. They wished to acquire more exotic models from Jaguar or Porsche, and used the VW as their bargaining chip. By the end of 1953, 2,173 were registered in the United States. By comparison, VW exported over 70,000 cars in 1953 alone. Hoffman was quite disappointed with these figures and ended his relationship with VW by 1954. | |||

In 1952, six Beetles, a bare Type 1 chassis and six [[Type 2 Transporters]] were showcased at the Canadian National Exhibition. Reactions to the strange little car were mixed. Some were excited about a new, economical vehicle coming to market, but others were opposed to buying a German product only 7 years removed from World War II. The one thing that everyone could a agree on, is that it was "different." Despite this reaction, Volkswagen of Canada was established in a Toronto farmhouse later that year. VWoC sold 8 cars in their first year of operation. In 1953, VWoC president Werner Jansen and a small crew took a Beetle and a Transporter on a promotional trip. Interest in the vehicles grew as a result, and soon after an extensive dealer network was established across Canada. | |||

= Major changes by year = | |||

===== 1938 ===== | |||

*44 hand-built VW38 pre-production models built. First split rear windshield. | |||

===== 1939 ===== | |||

*50 hand-built VW39 pre-production models built. | |||

*First use of stamping dies in production. | |||

*First production KdF-Wagens built, approximately 200, before factory shifts to wartime production. | |||

===== 1940-1942 ===== | |||

''Production dates January 1, 1940 to December 31, 1942<br>Chassis numbers 1-00,001 - 1-014,383<br>Engine numbers 1-00,001 - 1,017,113'' | |||

*Limited production of KdF-Wagen. Estimated 840 built through 1944. | |||

*Engine displacement 985cc producing 22bhp at 5.8:1 compression ratio. | |||

===== 1943-1944===== | |||

''Production date January 1, 1943 to December 31, 1944<br>Chassis Numbers 1-032,302 - 1-051,999<br>Engine numbers 1-017,114 - 1-077,683'' | |||

*Engine displacement increased to 1131cc producing 25bhp at 5.8:1 compression ratio. | |||

===== 1945 ===== | |||

''Production dates January 1, 1945 to December 31, 1945<br>Chassis numbers 1-052,000 - 1-053,814<br>Engine numbers 1-077,683 - 1-079,093'' | |||

*Renamed Volkswagen Type 1, production restarted under British control. | |||

===== 1946 ===== | |||

''Production dates January 1, 1946 to December 31, 1946<br>Chassis numbers 1-053,815 - 1-063,796<br>Engine numbers 1-079,094 - 1-090,732'' | |||

*Pushrod tubes get compressible ends, replacing springs. | |||

*Fuel tank raised. | |||

*Grease nipple added on brake cables. | |||

*Tires increase in size from 4.5x16 to 5.0x16. | |||

===== 1947 ===== | |||

''Production dates January 1, 1947 to December 31, 1947<br>Chassis numbers 1-063,797 - 1-072,743<br>Engine numbers 1-090,733 - 1-100,788'' | |||

*Reinforced rear hub bearings. | |||

*New lockable spare wheel bracket. | |||

*Manually operated summer/winter setting added to fan housing (flap which closes off half of air intake). | |||

*Chassis number added to tunnel between shifter and handbrake lever. | |||

===== 1948 ===== | |||

''Production dates January 1, 1948 to December 31, 1948<br>Chassis numbers 072,744 - 091,921<br>Engine numbers 100,789 - 122,649'' | |||

*First year of "Pope's nose" license plate light. | |||

*Steering column grooved longitudinally for steering lock. | |||

*Update brake drums. | |||

===== 1949 ===== | |||

''Production dates January 1, 1949 to December 31, 1949<br>Chassis numbers 091,922 - 138,554<br>Engine numbers 122,650 - 169,913'' | |||

*Solex carburetor becomes standard. | |||

*Domed air filter cover. | |||

*Intake manifold support. | |||

*Front torsion bars transposed - 5 in lower tube, 4 in upper tube. | |||

*Case hardened exhaust valve stems introduced. | |||

*"Elektron" alloy gearbox casing replaces magnesium. | |||

*Fusebox relocated to inside left hand front wing. | |||

*Pressing for number plate on engine lid removed. | |||

*Fuel tank shape changed, gauge strainer not fitted. | |||

*Fuel filler cap gets VW emblem. | |||

*Cylinders have higher phosphor content. | |||

*Starting crank hole removed. | |||

*Dash redesign. | |||

*Brown rubber front floor mats over the rubber floorpan covering. | |||

*Brake cables get Mipolam sheath. | |||

*Accelerator pedal roller increased in size. | |||

*Boge or Hemscheidt shock absorbers available. | |||

*Pull cable bonnet (hood) release, no lock on handle. | |||

*License plate indentation on rear deck lid removed. | |||

===== 1950 ===== | |||

''Production dates January 1, 1950 to December 31, 1950<br>Chassis numbers 138,655 - 220,133<br>Engine numbers 169,913 - 265,999'' | |||

*Small emblem hubcap replaced big emblem. | |||

*5 torsion leaves in each tube. | |||

*Gaskets added between cylinders and heads. | |||

*Bosch headlights become standard. | |||

*Tailpipe increased from 31 to 32mm. | |||

*Intake manifold now made of lightweight alloy. | |||

*Small cut-outs in tops of door windows. | |||

*Hydraulic brakes on export models. | |||

*Automatic engine cooling control by thermostatically controlled throttle ring. | |||

*Brake master cylinder reduced from 22.2mm to 19.5mm. | |||

*Rear brake cylinders reduced from 19.05mm to 15.9mm. | |||

*Optional cloth sunroof inroduced. | |||

*Hole for external crank handle discontinued on Cabriolet late in the model year. | |||

*Noise mufflers added to heating ducts. | |||

*Heat riser added to intake manifold. | |||

*Wrist pin offset to reduce piston slap. | |||

*Stronger alloys for exhaust valves and inserts. | |||

===== 1951 ===== | |||

''Production dates January 1, 1951 to December 31, 1951<br>Chassis numbers 220,134 - 313,829<br>Engine numbers 265,000 - 379,470'' | |||

*Chrome trim added to windshield seal. | |||

*Wolfsburg crest added above front hood handle. | |||

*Vent flaps (also known as crotch coolers) added to front quarter panels on export models. | |||

*Dual action shocks replace rear lever shocks. | |||

*Glove box door added to cabriolet models. | |||

*Single valve springs replace double springs. | |||

===== 1952 ===== | |||

''Production dates January 1, 1952 to December 31, 1952<br>Chassis numbers 318,830 - 428,156<br>Engine numbers 379,472 - 519,258'' | |||

*Crankshaft end play adjusted by 3 shims. | |||

*Tire size change from 5.00x16 to 5.6x15. | |||

*Torsion bar leaves increase from 5 to 6 for improved suspension travel. | |||

*New instrument panel layout from October 1952. | |||

*26PCI carburetor in late 1952. | |||

*2nd, 3rd and 4th gears fully synchronized, replacing old "crash box" transmission. | |||

*Window regulater reduced from 10 ½ to 3 ½ turns. | |||

*Glass vent windows replace body panel "crotch cooler" vents. | |||

*Heater control changed from pull knob to rotary knob. | |||

*T-style decklid handle introduced. | |||

*Dual brake/taillights replace single unit. | |||

*Turn indicator switch moved to steering column from dashboard. | |||

*Interior light moved to left side B pillar. | |||

*All models now feature glove box lid. | |||

*Larger reinforced bumpers. | |||

*Self parking wipers. | |||

*Crank starter hole discontinued on all models. | |||

*Widened body side trim. | |||

*Redesigned "Pope's nose" license plate light. | |||

===== 1953 ===== | |||

''Production dates January 1, 1953 to December 31, 1953<br>Chassis numbers 428,157 - 575,414<br>Engine numbers 519,259 - 695,281'' | |||

*Split rear window becomes one-piece oval on March 10, 1953. | |||

*Fuel filler neck widened from 40 to 80mm. | |||

*Lock button added to vent window latch. | |||

*Chrome plated ash tray handle. | |||

*Adjustable door striker plates. | |||

*Change to 3rd and 4th gear ratios. | |||

*Valve clearance changed to .004" | |||

*Carburetor and distributor with both vacuum and mechanical advance late in model year. | |||

*Generator output increased to 160 watts. | |||

*Break-in period for new engine dropped. | |||

*Torsion bar leaves increased from 6 to 8 in each tube. | |||

===== 1954 ===== | |||

''Production dates January 1, 1954 to December 31, 1954<br>Chassis numbers 575,415 - 781,884<br>Engine numbers 695,283 - 945,525'' | |||

* Engine displacement increased to 1192cc engine outputting 36hp at 6.1:1 compression ratio. | |||

*Larger intake valves. | |||

*Cylinder heads redesigned to improve cooling. | |||

*28PCI carburetor becomes standard. | |||

*Starter switch incorporated into ignition switch. | |||

*Three way interior light upgrade. | |||

*Engine compression ratio becomes 6.6:1 late in model year. | |||

*Air cleaner upgraded to oil-bath type. | |||

*Seat upholstery fabric quality improved. | |||

*Rubber retaining strap added to rear seat to prevent flipping forward while braking. | |||

===== 1955 ===== | |||

''Production dates January 1, 1955 to December 31, 1955<br>Chassis numbers 781,885 - 1,060,929<br>Engine numbers 945,527 - 1,277,347'' | |||

*Flashing blinkers replace semaphores on USA models. | |||

*Top window in tail light housing eliminated. | |||

*Gear lever moved forward. | |||

*Dished steering wheel. | |||

===== 1956 ===== | |||

''Production dates January 1, 1956 to December 31, 1956<br>Chassis numbers 1,060,930 - 1,394,119<br>Engine numbers 1,277,347 - 1,678,209'' | |||

*Sunroof reduced in size and changed from cloth fabric to plastic fabric. | |||

*Tail light housing raised 2 inches and becomes single lens. | |||

*Curved gear shift handle. | |||

*Bumper over-riders added. | |||

*Dual tail pipes added, chrome on export models and black enamel on standard models. | |||

*Steering wheel spoke moved lower, off-center. | |||

*Heater knob moved forward. | |||

*Fuel tank capacity increased. | |||

*Luggage compartment size increased. | |||

*Larger oil pump mounting shaft. | |||

*Fuel filter tap removed. | |||

*Copper plated fulcrum plates in universals. | |||

*More powerful starter motor. | |||

*Tubeless tires now standard equipment. | |||

*Front floor heater outlets moved rearward late in model year. | |||

*Front seat backs now adjustable. | |||

===== 1957 ===== | |||

''Production dates January 1, 1957 to December 31, 1957<br>Chassis numbers 1,394,120 - 1,774,680<br>Engine numbers 1,678,210 - 2,158,321'' | |||

*Optional sunroof size reduced again. | |||

*Larger engine oil galleries. | |||

*Ring and Pinion ratio changed. | |||

*New brake pedal design increases leverage. | |||

*Adjustable striker plates in door frames. | |||

===== 1958 ===== | |||

''Production dates January 1, 1958 to December 31, 1958<br>Chassis numbers 1,774,681 - 2,226,206<br>Engine numbers 2,156,322 - 2,721,313'' | |||

*Larger windshield. | |||

*Oval rear window replaced with larger glass. | |||

*Reinforcement added to frame head. | |||

*Redesigned instrument panel. | |||

*Radio grill moved to the left. | |||

*Front turn indicators moved to top of fenders. | |||

*Decklid redesigned. | |||

*Flat accelerator pedal replaces roller type. | |||

*Horizontal air inlets added to convertible models. | |||

*New style dished steering wheel. | |||

*Brake drum and shoe friction surfaces wider. | |||

*Upgraded clutch with stronger springs. | |||

*3rd and 4th gear ratios changed. | |||

===== 1959 ===== | |||

''Production dates January 1, 1959 to December 31, 1959<br>Chassis numbers 2,226,207 - 2,801,613<br>Engine numbers 2,721,314 - 3,424,453'' | |||

*Front suspension control arm bushings changed to needle rollers. | |||

*Chassis reinforced. | |||

*Sway bar added. | |||

*Improved fan belt. | |||

*Upgraded clutch springs. | |||

===== 1960 ===== | |||

''Production dates January 1, 1960 to July 31, 1960<br>Chassis numbers 2,801,614 - 3,192,506<br>Engine numbers 3,424,454 - 3,912,903'' | |||

*Recessed steering wheel for increased safety. | |||

*Damper added to steering linkage. | |||

*Steering box switches to worm-and-peg from worm and roller. | |||

*Generator output increases from 160 to 180 watts. | |||

*Outside door handles switched to push button type. | |||

*Padded sun visor. | |||

*Seat back contour changed. | |||

*Wolfsburg crest on front hood reduced color. | |||

*Last year for semaphores in Europe, Canada, Australia. | |||

===== 1961 ===== | |||

===== 1962 ===== | |||

===== 1963 ===== | |||

===== 1964 ===== | |||

===== 1965 ===== | |||

===== 1966 ===== | |||

===== 1967 ===== | |||

===== 1968 ===== | |||

===== 1969 ===== | |||

===== 1970 ===== | |||

===== 1971 ===== | |||

===== 1972 ===== | |||

===== 1973 ===== | |||

===== 1974 ===== | |||

===== 1975 ===== | |||

===== 1976 ===== | |||

===== 1977 ===== | |||

===== 1978 ===== | |||

===== 1979 ===== | |||

Latest revision as of 20:02, 12 July 2025

| Beetle | |

|---|---|

1949 Beetle Type 11 (Export Model) | |

| Overview | |

| Manufacturer | Volkswagen |

| Also called | |

| Production | 1938–2003: 21,529,464 built |

| Designer | Ferdinand Porsche |

| Variants | |

| Derivatives |

|

| Powertrain | |

| Engine | |

| Transmission |

|

| Dimensions | |

| Wheelbase | 2,400 mm (94.5 in) |

The Beetle—officially the Type 1, is an economy car that was manufactured and marketed by Volkswagen (VW) from 1938 until 2003.

It was designed by Ferdinand Porsche and features an air cooled rear-engine, two door coupe or cabriolet body-on-chassis design.

History

Josef Ganz's "Maikäfer" and the Standard Superior

The idea of a "people's car" can traced as far back as 1923, when a young Jewish Hungarian engineering student named Josef Ganz began sketching concepts for a "car for the masses." Ganz's design featured a mid-mounted engine, independent suspension and a streamlined body.

Being a student, Ganz did not have the funding to produce a prototype of his design, but instead began submitting articles on automotive design for various publications. Shortly after completing his studies in 1927, Ganz was hired as editor-in-chief of Klein-Motor-Sport (later renamed Motor-Kritik), where he continued to write articles promoting progressive design and the creation of a car for the average citizen.

In 1929, Josef Ganz contacted motorcycle manufacturers Zündapp, Ardie and DKW with assistance to build a prototype of his concept. The first prototype, the Ardie-Ganz, was built at Ardie in 1930 and a second one was completed at Adler in 1931, which was nicknamed the Maikäfer (‘May-Beetle').

Production of the first car based on Josef Ganz's designs and patents began in 1933. The Standard Superior, built by Standard Fahrzeugfabrik, featured a body-on-tubular chassis, 2-stroke air cooled mid-engine, and independent suspension with rear swing-axles. This car was advertised as the German "Volkswagen," or "people's car," pre-dating the incorporation of Volkswagenwerk GmbH in 1937. Superior production ceased in 1935.

Due to the antisemitic policies of the Nazi Party, Ganz's influence on the development of the Beetle was largely forgotten and has often been left out of official Volkswagen history. His contribution is still widely debated to this day.

Ferdinand Porsche's prototypes

In 1931, Zündapp requested Austrian engineer Ferdinand Porsche design and build a prototype for an "everyman's automobile." This led to the development of three prototypes (two saloons and one coupe) known as the Porsche Type 12. These prototypes features a U-channel center beam chassis, leaf spring suspension, worm-gear steering and hydraulic drum brakes. The drivetrain consisted of a Zündapp-built five-cylinder radial engine (as opposed to Porsche's preferred flat-four engine) and a combined gearbox differential transmission joined by a wet single disc clutch. The Type 12 laid the basic design foundation for what would eventually become the Beetle.

In 1932, Porsche was contacted by NSU Motorenwerke to design and build a prototype automobile. NSU wished to return to manufacturing cars after a period of exclusively building motorcycles. While Zündapp has requested use of their radial engine, NSU placed no such restrictions and gave Porsche full control of development. This resulted in the construction of three prototypes, with two different body styles, called the Type 32. These prototypes featured the rear air-cooled flat-four engine, central tube frame, front axle, rear swing axle and torsion bar suspension that would become quite familiar to Volkswagen owners in the subsequent decades.

Adolf Hitler

In 1924, a young Adolf Hitler spent nine months in Landsberg Prison as a result of his Nazi Party's failed coup the year prior. While serving his sentence, Hitler read several books about Henry Ford's development of mass production techniques. Hitler showed great interest in automobiles, despite never having learned to drive. The future chancellor came to admire Ford and made it among his political ambitions to bring affordable transportation to the people of Germany in the same manner which Ford had done in the United States.

Upon Hitler's rise to power in 1933, the German auto industry was limited to luxury models, which few Germans could afford. Only one German out of 50 owned a car. The newly appointed chancellor began to form plans to utilize state resources to develop an affordable automobile. At the 1933 Berlin Auto Show, he viewed a presentation of the Standard Superior by Josef Ganz. Hitler was quite impressed with the revolutionary design and low price of the Superior. Ganz, however, was arrested by the Gestapo shortly thereafter on falsified charges of blackmailing the German automotive industry. Ganz was eventually released and quickly fled Germany.

In May 1934, at a meeting at Berlin's Kaiserhof Hotel, Hitler outlined his request for a basic vehicle that could transport two adults and three children at 100 km/h while not using more than 7 litres of fuel per 100 km. The engine had to be powerful enough for sustained cruising on Germany's Autobahn, which was under construction at the time. Parts needed to be widely available and quickly and affordably exchanged. The engine had to be air-cooled to avoid radiators freezing during the winter months. It's platform must be easily adapted to a variety of uses, including military applications. This "People's Car" was to be made available to citizens of Germany through a stamp booklet savings plan, for under 1000 Reichsmarks. (At the time, the average weekly income was around 32 Reichsmarks.)

By June 1934, Hitler had assigned the task of development to Ferdinand Porsche. A design team was quickly assembled which included future Porsche designers Erwin Komenda and Karl Rabe. By October 1935, two prototypes known as, a sedan (V1) and convertible (V2), were complete and ready for testing. By 1936, three more prototypes (V3) were finished. These cars were designated Type 60 and built by hand in Porsche's Stuttgart workshop.

Hitler was impressed with the V3 prototype at the Berlin Auto Show and immediately ordered that it enter production. The Reichsverband der Deutsche Automobilindustrie, a special interest group representing German automakers, immediately pushed back against further development, seeing the low cost of the car as a threat to their business. This in turn caused Hitler to declare the project a wholly state-run enterprise of the national labor union, Deutsche Arbeitsfront.

A further thirty development models, known as V30, were produced for Porsche by Daimler-Benz. These vehicles underwent demanding tests through a variety of terrain and environmental conditions. Overall, these cars were subjected to a combined 1.8 million miles over the course of 1937. Though lacking a rear window, all V30s shared the distinctive round shape and the air-cooled, rear-mounted engine of final production models.

The final design added a split rear windshield. In 1938, 44 pre-production models known as the VW38 were built by hand in Stuttgart. The very first convertible model from this batch (chassis 38/31) was presented to Hitler as a gift. Fifty more cars followed in 1939 (VW39), and though still hand-built, some parts utilized the new stamping dies built for production.

The KdF Wagen and a new factory

By 1937, it was decided that a new factory was needed for production of the "people's car." Land was seized in Northern Germany, along the banks of the Mitteland Canal in the village of Fallersleben. Construction of the new factory began in February 1938.

On May 26, 1938, a cornerstone-laying ceremony was held at the site of the new factory with typical Nazi-party fanfare and propaganda photo-ops. In the speech given by Adolph Hitler, he announced the new automobile to be built on the site will be named "Kraft-durch-Freude-Wagen" ("Strength Through Joy Car," abbreviated to KdF-Wagen) after the leisure organization operated by Deutsche Arbeitsfront. He also outlined his plan for construction of a grand factory city known as "Stadt des KdF-Wagens bei Fallersleben" ("City of the Strength Through Joy car at Fallersleben") to be built on the southern side of the canal.

Production of the KdF Wagen was scheduled to begin in the Autumn of 1939. Nazi propaganda claimed the new factory was expected to produce 500,000 vehicles per year, all for the benefit of the German people. However, only about 200 vehicles were produced prior to the outbreak of war. Most of these early production vehicles were given to Nazi Party officials and few, if any, citizens received their car through the stamp-booklet savings plan.

Wartime production

On September 1, 1939, Nazi Germany invaded Poland. Two days later, France and Britain declared war on Germany, signaling the start of World War II.

Almost immediately, the factory at KdF-Stadt shifted to wartime production. The primary vehicles produced during this time were the Porsche-designed Type 82 Kübelwagen and Type 166 Schwimmwagen. A handful of light vehicles based on the KdF-Wagen were constructed, such as the Type 82E Kommandeurswagen. The manufacturing resources of the factory were also used to produce other military equipment including stoves, aircraft parts and assemblies for the V1 flying bomb. A very limited number of civilian KdF-Wagens were built during the war, which were primarily handed to high-ranking Nazi Party members.

Production at KdF-Stadt was halted in 1944 after the factory sustained significant damage due to Allied bombing. Much of the critical equipment was moved into bunkers, with expectation that production would resume after hostilities ceased.

Due to gasoline shortages in the late stages of the war, a small number of vehicles were converted to utilize wood-burning gas generators. These became known as "Holzbrenner" Beetles.

In early 1945, the tide of war had turned. American troops were advancing deeper into Germany and over two thirds of the factory lay in ruin. Some workers, many of whom were foreign forced laborers, began destroying as much as they could of what was left.

Allied occupation

KdF-Stadt was captured by US troops on April 11, 1945. Over 7,700 forced laborers were liberated from the factory. On May 25, 1945, the city was renamed Wolfsburg, after the nearby Wolfsburg Castle. The Americans occupied Wolfsburg until June 1945, at which time it became part of the British Occupation Zone.

The British intended to dismantle the factory and ship all useable assets to Britain under the Morgenthau Plan. However, no British automaker was interested in the factory. Sir William Rootes, head of the British Rootes Group, told Hirst the project would fail within two years, is quoted as saying the car "is quite unattractive to the average motorcar buyer, is too ugly and too noisy. If you think you're going to build cars in this place, you're a bloody fool."

Responsibility for the city and the factory then fell to a division of the Royal Electrical and Mechanical Engineers commanded by Major Ivan Hirst. At the time, the bombed-out factory was being utilized as a repair shop for Allied military and transport vehicles. Hirst soon discovered that much of the original tooling and parts remained undamaged. His team assembled a few complete vehicles from existing parts and saw the potential in the quirky little car. Realizing that occupation forces required a cheap and reliable form of transportation during Germany's reconstruction, Hirst saw an opportunity. The car was presented to the British Military, who promptly placed an order for 20,000 vehicles. Two weeks later, the order was doubled to 40,000.

Hirst quickly grew the workforce from the remaining 450 post-war workers to over 6,500 employees. At this time, the car reverted to it's original name, "Volkswagen" (People's Car) and the model was designated the "Type 1." The first production Type 1 rolled off the assembly line on December 27, 1945. By March 1946, the Wolfsburg plant was producing 1,000 cars per month, painted army green for the British military. Early production numbers were limited by rationing and a shortage of raw materials, such as steel, batteries, textiles, and glass. Early Beetle roof sections were fashioned out of two pieces of steel, due to larger sheets being unavailable. Hirst convinced the British government to allocate the necessary materials, as the operation of the factory stimulated economic growth and increased employment during post-war reconstruction.

1947 signaled a transition into building a civilian version of the Type 1. For the first time, chrome bumpers, hubcaps and body trim were fitted. Engine displacement was increased to 1131cc and had an output of 25hp. Models destined for export markets were designated and marketed as the Type 11. Civilian output reached 9,000 units in 1947, which increased to almost 20,000 in 1948.

In March 1948, the British offered the company to Ford, free of charge. Henry Ford II and Ford chairman Ernest Breech travelled to West Germany to tour the factory. When Ford asked Breech for his opinion, Breech said, "Mr. Ford, I don't think what we're being offered here is worth a damn!"

Returning Volkswagen to German control

After the British-led restart of production and failing to find a buyer for the company, Hirst began to look for a successor to return day-to-day operations back to the Germans. Former Opel director Heinrich Nordhoff was offered a position as manager. Despite being highly critical of the Volkswagen's unconventional engineering in the past, Nordhoff had few other opportunities. Though he was never a member of the Nazi Party, he had been barred from work in the American sector due to his position at the Opel factory building German military vehicles. Nordhoff accepted and took control of the Wolfsburg plant on January 1, 1948.

Under Nordhoff's leadership, the British Military Government slowly took a backseat to operations. On October 8, 1949, ownership of Volkswagenwerk GmbH was transferred to the newly-formed West German government.

Expansion and export

Upon joining Volkswagen, Heinrich Nordhoff brought years of managerial, technical, and mass production experience to the young company. Nordhoff settled on a "one model" plan, where the product would retain a similar outward appearance, with minor changes made to improve performance and efficiency. Right away, he saw the need to expand the market. Though under British control, a strong export market had been created in a handful of European countries, Nordhoff realized that in order to survive, Volkswagen would have to break into the American market. At the time, The United States had the strongest post-war economy and most stable currency in the world.

Norhoff recruited Ben Pon, a highly successful Dutch importer, to introduce the Volkswagen to the American market. Pon traveled to New York in 1949, bringing a Beetle along, to try and convince European Car dealers to sell the car. After a month of attempts, Pon was ultimately unsuccessful. He ended up selling the Beetle for just $800 in order to pay for his expenses. While a few VWs had been brought back to the United States by returning GIs, Norhoff was determined to break into the market. He traveled to the US himself later in 1949, but was no more successful, again selling only one car.

In 1950, Max Hoffman took interest in Volkswagen. Hoffman was an established and successful American importer of European autos. Hoffman established a small American sales network which managed to sell 330 VWs in the first year. Many of the dealers who purchased Volkswagens did so in hope to establish a good report with Hoffman. They wished to acquire more exotic models from Jaguar or Porsche, and used the VW as their bargaining chip. By the end of 1953, 2,173 were registered in the United States. By comparison, VW exported over 70,000 cars in 1953 alone. Hoffman was quite disappointed with these figures and ended his relationship with VW by 1954.

In 1952, six Beetles, a bare Type 1 chassis and six Type 2 Transporters were showcased at the Canadian National Exhibition. Reactions to the strange little car were mixed. Some were excited about a new, economical vehicle coming to market, but others were opposed to buying a German product only 7 years removed from World War II. The one thing that everyone could a agree on, is that it was "different." Despite this reaction, Volkswagen of Canada was established in a Toronto farmhouse later that year. VWoC sold 8 cars in their first year of operation. In 1953, VWoC president Werner Jansen and a small crew took a Beetle and a Transporter on a promotional trip. Interest in the vehicles grew as a result, and soon after an extensive dealer network was established across Canada.

Major changes by year

1938

- 44 hand-built VW38 pre-production models built. First split rear windshield.

1939

- 50 hand-built VW39 pre-production models built.

- First use of stamping dies in production.

- First production KdF-Wagens built, approximately 200, before factory shifts to wartime production.

1940-1942

Production dates January 1, 1940 to December 31, 1942

Chassis numbers 1-00,001 - 1-014,383

Engine numbers 1-00,001 - 1,017,113

- Limited production of KdF-Wagen. Estimated 840 built through 1944.

- Engine displacement 985cc producing 22bhp at 5.8:1 compression ratio.

1943-1944

Production date January 1, 1943 to December 31, 1944

Chassis Numbers 1-032,302 - 1-051,999

Engine numbers 1-017,114 - 1-077,683

- Engine displacement increased to 1131cc producing 25bhp at 5.8:1 compression ratio.

1945

Production dates January 1, 1945 to December 31, 1945

Chassis numbers 1-052,000 - 1-053,814

Engine numbers 1-077,683 - 1-079,093

- Renamed Volkswagen Type 1, production restarted under British control.

1946

Production dates January 1, 1946 to December 31, 1946

Chassis numbers 1-053,815 - 1-063,796

Engine numbers 1-079,094 - 1-090,732

- Pushrod tubes get compressible ends, replacing springs.

- Fuel tank raised.

- Grease nipple added on brake cables.

- Tires increase in size from 4.5x16 to 5.0x16.

1947

Production dates January 1, 1947 to December 31, 1947

Chassis numbers 1-063,797 - 1-072,743

Engine numbers 1-090,733 - 1-100,788

- Reinforced rear hub bearings.

- New lockable spare wheel bracket.

- Manually operated summer/winter setting added to fan housing (flap which closes off half of air intake).

- Chassis number added to tunnel between shifter and handbrake lever.

1948

Production dates January 1, 1948 to December 31, 1948

Chassis numbers 072,744 - 091,921

Engine numbers 100,789 - 122,649

- First year of "Pope's nose" license plate light.

- Steering column grooved longitudinally for steering lock.

- Update brake drums.

1949

Production dates January 1, 1949 to December 31, 1949

Chassis numbers 091,922 - 138,554

Engine numbers 122,650 - 169,913

- Solex carburetor becomes standard.

- Domed air filter cover.

- Intake manifold support.

- Front torsion bars transposed - 5 in lower tube, 4 in upper tube.

- Case hardened exhaust valve stems introduced.

- "Elektron" alloy gearbox casing replaces magnesium.

- Fusebox relocated to inside left hand front wing.

- Pressing for number plate on engine lid removed.

- Fuel tank shape changed, gauge strainer not fitted.

- Fuel filler cap gets VW emblem.

- Cylinders have higher phosphor content.

- Starting crank hole removed.

- Dash redesign.

- Brown rubber front floor mats over the rubber floorpan covering.

- Brake cables get Mipolam sheath.

- Accelerator pedal roller increased in size.

- Boge or Hemscheidt shock absorbers available.

- Pull cable bonnet (hood) release, no lock on handle.

- License plate indentation on rear deck lid removed.

1950

Production dates January 1, 1950 to December 31, 1950

Chassis numbers 138,655 - 220,133

Engine numbers 169,913 - 265,999

- Small emblem hubcap replaced big emblem.

- 5 torsion leaves in each tube.

- Gaskets added between cylinders and heads.

- Bosch headlights become standard.

- Tailpipe increased from 31 to 32mm.

- Intake manifold now made of lightweight alloy.

- Small cut-outs in tops of door windows.

- Hydraulic brakes on export models.

- Automatic engine cooling control by thermostatically controlled throttle ring.

- Brake master cylinder reduced from 22.2mm to 19.5mm.

- Rear brake cylinders reduced from 19.05mm to 15.9mm.

- Optional cloth sunroof inroduced.

- Hole for external crank handle discontinued on Cabriolet late in the model year.

- Noise mufflers added to heating ducts.

- Heat riser added to intake manifold.

- Wrist pin offset to reduce piston slap.

- Stronger alloys for exhaust valves and inserts.

1951

Production dates January 1, 1951 to December 31, 1951

Chassis numbers 220,134 - 313,829

Engine numbers 265,000 - 379,470

- Chrome trim added to windshield seal.

- Wolfsburg crest added above front hood handle.

- Vent flaps (also known as crotch coolers) added to front quarter panels on export models.

- Dual action shocks replace rear lever shocks.

- Glove box door added to cabriolet models.

- Single valve springs replace double springs.

1952

Production dates January 1, 1952 to December 31, 1952

Chassis numbers 318,830 - 428,156

Engine numbers 379,472 - 519,258

- Crankshaft end play adjusted by 3 shims.

- Tire size change from 5.00x16 to 5.6x15.

- Torsion bar leaves increase from 5 to 6 for improved suspension travel.

- New instrument panel layout from October 1952.

- 26PCI carburetor in late 1952.

- 2nd, 3rd and 4th gears fully synchronized, replacing old "crash box" transmission.

- Window regulater reduced from 10 ½ to 3 ½ turns.

- Glass vent windows replace body panel "crotch cooler" vents.

- Heater control changed from pull knob to rotary knob.

- T-style decklid handle introduced.

- Dual brake/taillights replace single unit.

- Turn indicator switch moved to steering column from dashboard.

- Interior light moved to left side B pillar.

- All models now feature glove box lid.

- Larger reinforced bumpers.

- Self parking wipers.

- Crank starter hole discontinued on all models.

- Widened body side trim.

- Redesigned "Pope's nose" license plate light.

1953

Production dates January 1, 1953 to December 31, 1953

Chassis numbers 428,157 - 575,414

Engine numbers 519,259 - 695,281

- Split rear window becomes one-piece oval on March 10, 1953.

- Fuel filler neck widened from 40 to 80mm.

- Lock button added to vent window latch.

- Chrome plated ash tray handle.

- Adjustable door striker plates.

- Change to 3rd and 4th gear ratios.

- Valve clearance changed to .004"

- Carburetor and distributor with both vacuum and mechanical advance late in model year.

- Generator output increased to 160 watts.

- Break-in period for new engine dropped.

- Torsion bar leaves increased from 6 to 8 in each tube.

1954

Production dates January 1, 1954 to December 31, 1954

Chassis numbers 575,415 - 781,884

Engine numbers 695,283 - 945,525

- Engine displacement increased to 1192cc engine outputting 36hp at 6.1:1 compression ratio.

- Larger intake valves.

- Cylinder heads redesigned to improve cooling.

- 28PCI carburetor becomes standard.

- Starter switch incorporated into ignition switch.

- Three way interior light upgrade.

- Engine compression ratio becomes 6.6:1 late in model year.

- Air cleaner upgraded to oil-bath type.

- Seat upholstery fabric quality improved.

- Rubber retaining strap added to rear seat to prevent flipping forward while braking.

1955

Production dates January 1, 1955 to December 31, 1955

Chassis numbers 781,885 - 1,060,929

Engine numbers 945,527 - 1,277,347

- Flashing blinkers replace semaphores on USA models.

- Top window in tail light housing eliminated.

- Gear lever moved forward.

- Dished steering wheel.

1956

Production dates January 1, 1956 to December 31, 1956

Chassis numbers 1,060,930 - 1,394,119

Engine numbers 1,277,347 - 1,678,209

- Sunroof reduced in size and changed from cloth fabric to plastic fabric.

- Tail light housing raised 2 inches and becomes single lens.

- Curved gear shift handle.

- Bumper over-riders added.

- Dual tail pipes added, chrome on export models and black enamel on standard models.

- Steering wheel spoke moved lower, off-center.

- Heater knob moved forward.

- Fuel tank capacity increased.

- Luggage compartment size increased.

- Larger oil pump mounting shaft.

- Fuel filter tap removed.

- Copper plated fulcrum plates in universals.

- More powerful starter motor.

- Tubeless tires now standard equipment.

- Front floor heater outlets moved rearward late in model year.

- Front seat backs now adjustable.

1957

Production dates January 1, 1957 to December 31, 1957

Chassis numbers 1,394,120 - 1,774,680

Engine numbers 1,678,210 - 2,158,321

- Optional sunroof size reduced again.

- Larger engine oil galleries.

- Ring and Pinion ratio changed.

- New brake pedal design increases leverage.

- Adjustable striker plates in door frames.

1958

Production dates January 1, 1958 to December 31, 1958

Chassis numbers 1,774,681 - 2,226,206

Engine numbers 2,156,322 - 2,721,313

- Larger windshield.

- Oval rear window replaced with larger glass.

- Reinforcement added to frame head.

- Redesigned instrument panel.

- Radio grill moved to the left.

- Front turn indicators moved to top of fenders.

- Decklid redesigned.

- Flat accelerator pedal replaces roller type.

- Horizontal air inlets added to convertible models.

- New style dished steering wheel.

- Brake drum and shoe friction surfaces wider.

- Upgraded clutch with stronger springs.

- 3rd and 4th gear ratios changed.

1959

Production dates January 1, 1959 to December 31, 1959

Chassis numbers 2,226,207 - 2,801,613

Engine numbers 2,721,314 - 3,424,453

- Front suspension control arm bushings changed to needle rollers.

- Chassis reinforced.

- Sway bar added.

- Improved fan belt.

- Upgraded clutch springs.

1960

Production dates January 1, 1960 to July 31, 1960

Chassis numbers 2,801,614 - 3,192,506

Engine numbers 3,424,454 - 3,912,903

- Recessed steering wheel for increased safety.

- Damper added to steering linkage.

- Steering box switches to worm-and-peg from worm and roller.

- Generator output increases from 160 to 180 watts.

- Outside door handles switched to push button type.

- Padded sun visor.

- Seat back contour changed.

- Wolfsburg crest on front hood reduced color.

- Last year for semaphores in Europe, Canada, Australia.